RENEWABLE ENERGY

Wind/Solar Power Plants

INDUSTRY

Shipbuilding/Automotive/Railway

FURNITURE

Office/Indoor-Outdoor

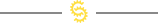

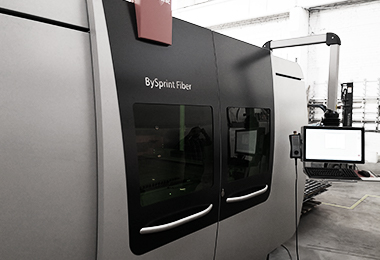

From 01 March 2018, UAB “ABEPA” began to realize project DPT pramonei LT+ ( HIT Industry LT+). On 2018 UAB “ABEPA” also began to bring out a Didelio poveikio technologijų diegimas UAB “ABEPA”

(High Impact Technologies Instill in UAB “ABEPA”) project. By this project, company is seeking to intensify the industry base by gaining and introducing a technological mechanism which is assigned to the high impact technologies.

The project is going to be fulfill according to Lithuanian 2014-2020 European Union funding Investment activity 3rd priority program “Smulkiojo ir vidutinio verslo konkurencingumo skatinimas” (A competitiveness stimulation of small and medium-sized enterprises) means “DPT pramonei LT+” (03.3.1-LVPA-K-841).In order to realize the project, regional European Union expansion funding committed 191835 EUR. This funding is going to cover 45prc. of project expenses and strongly increase companies possibilities reach the project goals. The project supposed to be realized by 29 December 2018.

From 01 March 2018, UAB “ABEPA” began to realize project DPT pramonei LT+ ( HIT Industry LT+). On 2018 UAB “ABEPA” also began to bring out a Didelio poveikio technologijų diegimas UAB “ABEPA”

(High Impact Technologies Instill in UAB “ABEPA”) project. By this project, company is seeking to intensify the industry base by gaining and introducing a technological mechanism which is assigned to the high impact technologies.

The project is going to be fulfill according to Lithuanian 2014-2020 European Union funding Investment activity 3rd priority program “Smulkiojo ir vidutinio verslo konkurencingumo skatinimas” (A competitiveness stimulation of small and medium-sized enterprises) means “DPT pramonei LT+” (03.3.1-LVPA-K-841).In order to realize the project, regional European Union expansion funding committed 191835 EUR. This funding is going to cover 45prc. of project expenses and strongly increase companies possibilities reach the project goals. The project supposed to be realized by 29 December 2018.

UAB “ABEPA” began to realize a project Auditas priemonei LT 4th of February, 2019, Kaunas. In 2018, UAB “ABEPA” started to realize the project „Improvement of energy efficiency in UAB “ABEPA”. With the help of this project, the company seeks to provide the means to increase the efficiency of the energy, by investing into internal audit of the company.

The project will be implemented in accordance with the measure of priority 4 of the investment operational program “Promotion of Energy Efficiency and Renewable Energy Production and Use” of the European Union funds for 2014-2020 (04.2.1-LVPA-K-804).

For the implementation of the project, the European regional development fund allocated EUR6300. This amount is going to cover 70 percent the costs of the project and going to contribute significantly to the company’s ability to achieve the projects objectives.

The project is planned to be implemented by 14 June, 2019.

UAB “ABEPA” began to realize a project Auditas priemonei LT 4th of February, 2019, Kaunas. In 2018, UAB “ABEPA” started to realize the project „Improvement of energy efficiency in UAB “ABEPA”. With the help of this project, the company seeks to provide the means to increase the efficiency of the energy, by investing into internal audit of the company.

The project will be implemented in accordance with the measure of priority 4 of the investment operational program “Promotion of Energy Efficiency and Renewable Energy Production and Use” of the European Union funds for 2014-2020 (04.2.1-LVPA-K-804).

For the implementation of the project, the European regional development fund allocated EUR6300. This amount is going to cover 70 percent the costs of the project and going to contribute significantly to the company’s ability to achieve the projects objectives.

The project is planned to be implemented by 14 June, 2019.

On 2019 UAB “ABEPA” began to implement a project Gamybinių procesų skaitmeninimas UAB “Abepa” (Digitalization of manufacturing processes at UAB “Abepa”). By this project, company is seeking to improve its manufacturing works productivity with implementation of digitaly reinforced manufacturing equipment.

The project is going to be fulfill according to Lithuanian 2014-2020 European Union funding Investment activity 3rd priority program “Smulkiojo ir vidutinio verslo konkurencingumo skatinimas” (A competitiveness stimulation of small and medium-sized enterprises) means “Pramonės skaitmeninimas LT“ (Industry digitalisation LT), (03.3.1-LVPA-K-854).

In order to realize the project, regional European Union expansion funding committed 160231 EUR. This funding is going to cover 45prc. of project expenses and strongly increase companies possibilities reach the project goals.

The project supposed to be realized by 3rd March 2021 and funded by the European Regional Development Fund.

On 2019 UAB “ABEPA” began to implement a project Gamybinių procesų skaitmeninimas UAB “Abepa” (Digitalization of manufacturing processes at UAB “Abepa”). By this project, company is seeking to improve its manufacturing works productivity with implementation of digitaly reinforced manufacturing equipment.

The project is going to be fulfill according to Lithuanian 2014-2020 European Union funding Investment activity 3rd priority program “Smulkiojo ir vidutinio verslo konkurencingumo skatinimas” (A competitiveness stimulation of small and medium-sized enterprises) means “Pramonės skaitmeninimas LT“ (Industry digitalisation LT), (03.3.1-LVPA-K-854).

In order to realize the project, regional European Union expansion funding committed 160231 EUR. This funding is going to cover 45prc. of project expenses and strongly increase companies possibilities reach the project goals.

The project supposed to be realized by 3rd March 2021 and funded by the European Regional Development Fund.

UAB “ABEPA” has started to implement the Renewable energy resources for idustry LT+ project

In 2020, UAB “ABEPA” started implementing the project Implementation of renewable energy resources in UAB Abepa. With this project, the company aims to reduce the intensity of energy consumption in the company by increasing RES production and consumption. In order to achieve the goal of this project, renewable energy equipment (solar photovoltaic power plant), that reduces energy intensity in the company, will be purchased and installed during the project.

The project will be implemented with the Lithuanian 4th priority "Promotion of energy efficiency and renewable energy production and use" measure "Renewable energy recources for industry LT+" of the European Union funds investment operational program for 2014-2020 (04.2.1-LVPA-K-836).

An amount of EUR 99 781,99 was allocated from the European Regional development fund for the implementation of the project. This amount will cover 60% projects costs and thus make a strong contribution to the company‘s ability to achieve project objectives.

Project is planned to be implemented by 2021 December 31.

UAB “ABEPA” has started to implement the Renewable energy resources for idustry LT+ project

In 2020, UAB “ABEPA” started implementing the project Implementation of renewable energy resources in UAB Abepa. With this project, the company aims to reduce the intensity of energy consumption in the company by increasing RES production and consumption. In order to achieve the goal of this project, renewable energy equipment (solar photovoltaic power plant), that reduces energy intensity in the company, will be purchased and installed during the project.

The project will be implemented with the Lithuanian 4th priority "Promotion of energy efficiency and renewable energy production and use" measure "Renewable energy recources for industry LT+" of the European Union funds investment operational program for 2014-2020 (04.2.1-LVPA-K-836).

An amount of EUR 99 781,99 was allocated from the European Regional development fund for the implementation of the project. This amount will cover 60% projects costs and thus make a strong contribution to the company‘s ability to achieve project objectives.

Project is planned to be implemented by 2021 December 31.

In 2021, UAB "Abepa" started implementing the project Digitization of UAB "Abepa" production processes. With this project, the company aims to digitize part of the company's production processes and thus create conditions for the growth of labour productivity. To achieve the objective of this project, a set of equipment with digital technology will be purchased and installed during the project.

The project will be implemented under the measure "Digitisation of Industry LT" (03.3.1-LVPA-K-854) of priority 3 "Promotion of competitiveness of small and medium-sized enterprises" of the European Union Funds Investment Operational Programme 2014-2020.

An amount of EUR 227646 was allocated from the European Regional Development Fund for the implementation of the project. This amount will cover 45% of the project costs and thus contribute significantly to the company's ability to achieve the project's objectives.

The project is expected to be implemented by 10 February 2023.

In 2021, UAB "Abepa" started implementing the project Digitization of UAB "Abepa" production processes. With this project, the company aims to digitize part of the company's production processes and thus create conditions for the growth of labour productivity. To achieve the objective of this project, a set of equipment with digital technology will be purchased and installed during the project.

The project will be implemented under the measure "Digitisation of Industry LT" (03.3.1-LVPA-K-854) of priority 3 "Promotion of competitiveness of small and medium-sized enterprises" of the European Union Funds Investment Operational Programme 2014-2020.

An amount of EUR 227646 was allocated from the European Regional Development Fund for the implementation of the project. This amount will cover 45% of the project costs and thus contribute significantly to the company's ability to achieve the project's objectives.

The project is expected to be implemented by 10 February 2023.

In 2024, UAB "Abepa" began implementing the project "Expansion of UAB 'Abepa' Export Markets". Through this project, the company will participate in international exhibitions

held abroad, thereby securing new export markets and expanding existing ones, while aiming to increase the company's competitiveness and international presence.

The project will be implemented under the 2022-2030 Development Program managed by the Ministry of Economy and Innovation of the Republic of Lithuania, specifically

within the economic transformation and competitiveness development program's progress measure No. 05-001-01-11-04 "Implement Measures to Promote Export Competitiveness,"

under the activity "Promotion of SME Internationalization and New Export Market Identification Activities (Central and Western Lithuania Region)."

In 2024, UAB "Abepa" began implementing the project "Expansion of UAB 'Abepa' Export Markets". Through this project, the company will participate in international exhibitions

held abroad, thereby securing new export markets and expanding existing ones, while aiming to increase the company's competitiveness and international presence.

The project will be implemented under the 2022-2030 Development Program managed by the Ministry of Economy and Innovation of the Republic of Lithuania, specifically

within the economic transformation and competitiveness development program's progress measure No. 05-001-01-11-04 "Implement Measures to Promote Export Competitiveness,"

under the activity "Promotion of SME Internationalization and New Export Market Identification Activities (Central and Western Lithuania Region)."

The total project value (including eligible and ineligible expenses) is EUR 138,364, of which EUR 69,182 has been allocated from the European Regional Development Fund.

This amount will cover 50 percent of the project's eligible expenses and will significantly contribute to the company's ability to achieve the project goals.

Project implementation period: June 10, 2024 – November 30, 2025.

In 2024, UAB "Abepa" began implementing the project "Improvement of UAB 'Abepa' Energy Efficiency." Through this project, the company aims to implement

an energy efficiency improvement solution, thereby reducing greenhouse gas emissions in the technological process by at least 30 percent.

In 2024, UAB "Abepa" began implementing the project "Improvement of UAB 'Abepa' Energy Efficiency." Through this project, the company aims to implement

an energy efficiency improvement solution, thereby reducing greenhouse gas emissions in the technological process by at least 30 percent.

As an innovative metalworking company, UAB "Abepa" has assessed the annually increasing energy consumption, growing ecological trends, and the company's potential to

use energy more efficiently by implementing new solutions. The implemented project, by introducing a new technological solution, would not only contribute to reducing

primary energy consumption, decreasing greenhouse gas emissions, and positively impacting Lithuania's climate change efforts in addressing air pollution and efficient

resource use, but also help the company strengthen its position among competitors and end-users on a global scale.

The project will be implemented under the 2022-2030 Development Program managed by the Ministry of Economy and Innovation of the Republic of Lithuania,

specifically within the economic transformation and competitiveness development program's progress measure No. 05-001-01-04-02 "Encourage Companies to Transition

Towards a Climate-Neutral Economy," under the activity "Increase Energy Efficiency in Industrial Companies."

The project value is EUR 1,602,000, of which EUR 827,005 has been allocated from the European Regional Development Fund. This amount will cover 55

percent of the project's eligible expenses and will significantly contribute to the company's ability to achieve the project goals. The project is co-financed by the

European Union.

Project implementation period: August 22, 2024 – August 22, 2027.

Contact person: Paulius Beniušis, Director.

In 2024, UAB "Abepa" began implementing the project "Development of UAB 'Abepa' Employees' Skills."

In 2024, UAB "Abepa" began implementing the project "Development of UAB 'Abepa' Employees' Skills."

UAB "Abepa" is an innovative company with long-standing experience in the metalworking industry. Given the company's annually growing potential, its

active orientation towards automated computerized solutions implemented within the company, and the potential to develop new product creation activities,

it has been determined that it is particularly important for the company to enhance the qualifications of its human resources in parallel with its ongoing

expansion. Through this project, the company aims to improve its employees' skills in flexible product development, production, process management technologies,

and cybersecurity.

The project will be implemented under the 2022-2030 Development Program managed by the Ministry of Economy and Innovation of the Republic of Lithuania,

specifically within the economic transformation and competitiveness development program's progress measure No. 05-001-01-05-07 "Create a Coherent System

for Promoting Innovation," under the activity "Develop Skills Required for Very Small, Small, and Medium-Sized Enterprises."

The project value is EUR 140,524.61, of which EUR 84,363.95 has been allocated from the European Regional Development Fund. This amount will cover 60 percent

of the project's eligible expenses and will significantly contribute to the company's ability to achieve the project goals. The project is co-financed by the European Union.

Project implementation period: August 28, 2024 – August 28, 2026.

Contact person: Paulius Beniušis, Director.

Career

Metal products are our daily life. We work with well-known foreign clients,

emphasizing quality, and complete 96% of orders on time. To achieve even better results, we are

constantly expanding and looking for professionals in our field. If you are motivated, knowledgeable

in metal processing – we are looking for you! In our company, you will have an excellent opportunity

to improve in your professional activities, develop your skills, and grow as a specialist!

What do we offer?

The opportunity to grow and improve among industry professionals, and of course, competitive salary.

Vacancy announcements

From 01 March 2018, UAB “ABEPA” began to realize project DPT pramonei LT+ ( HIT Industry LT+). On 2018 UAB “ABEPA” also began to bring out a Didelio poveikio technologijų diegimas UAB “ABEPA”

(High Impact Technologies Instill in UAB “ABEPA”) project. By this project, company is seeking to intensify the industry base by gaining and introducing a technological mechanism which is assigned to the high impact technologies.

The project is going to be fulfill according to Lithuanian 2014-2020 European Union funding Investment activity 3rd priority program “Smulkiojo ir vidutinio verslo konkurencingumo skatinimas” (A competitiveness stimulation of small and medium-sized enterprises) means “DPT pramonei LT+” (03.3.1-LVPA-K-841).In order to realize the project, regional European Union expansion funding committed 191835 EUR. This funding is going to cover 45prc. of project expenses and strongly increase companies possibilities reach the project goals. The project supposed to be realized by 29 December 2018.

From 01 March 2018, UAB “ABEPA” began to realize project DPT pramonei LT+ ( HIT Industry LT+). On 2018 UAB “ABEPA” also began to bring out a Didelio poveikio technologijų diegimas UAB “ABEPA”

(High Impact Technologies Instill in UAB “ABEPA”) project. By this project, company is seeking to intensify the industry base by gaining and introducing a technological mechanism which is assigned to the high impact technologies.

The project is going to be fulfill according to Lithuanian 2014-2020 European Union funding Investment activity 3rd priority program “Smulkiojo ir vidutinio verslo konkurencingumo skatinimas” (A competitiveness stimulation of small and medium-sized enterprises) means “DPT pramonei LT+” (03.3.1-LVPA-K-841).In order to realize the project, regional European Union expansion funding committed 191835 EUR. This funding is going to cover 45prc. of project expenses and strongly increase companies possibilities reach the project goals. The project supposed to be realized by 29 December 2018.

In 2024, UAB "Abepa" began implementing the project "Expansion of UAB 'Abepa' Export Markets". Through this project, the company will participate in international exhibitions

held abroad, thereby securing new export markets and expanding existing ones, while aiming to increase the company's competitiveness and international presence.

The project will be implemented under the 2022-2030 Development Program managed by the Ministry of Economy and Innovation of the Republic of Lithuania, specifically

within the economic transformation and competitiveness development program's progress measure No. 05-001-01-11-04 "Implement Measures to Promote Export Competitiveness,"

under the activity "Promotion of SME Internationalization and New Export Market Identification Activities (Central and Western Lithuania Region)."

In 2024, UAB "Abepa" began implementing the project "Expansion of UAB 'Abepa' Export Markets". Through this project, the company will participate in international exhibitions

held abroad, thereby securing new export markets and expanding existing ones, while aiming to increase the company's competitiveness and international presence.

The project will be implemented under the 2022-2030 Development Program managed by the Ministry of Economy and Innovation of the Republic of Lithuania, specifically

within the economic transformation and competitiveness development program's progress measure No. 05-001-01-11-04 "Implement Measures to Promote Export Competitiveness,"

under the activity "Promotion of SME Internationalization and New Export Market Identification Activities (Central and Western Lithuania Region)."